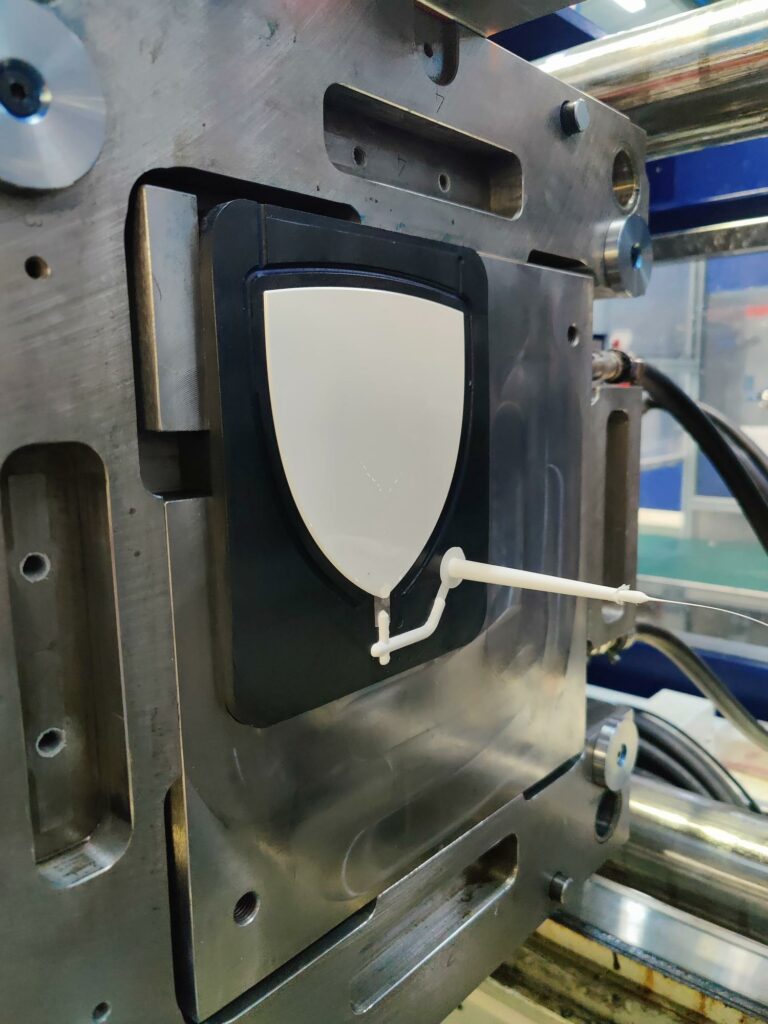

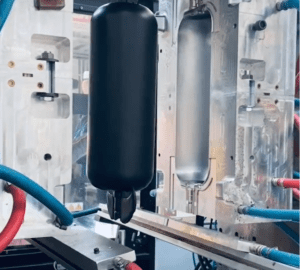

+ The SAMFAST project aimed to study and evaluate the various technologies for 3D printing of polymer moulds, to validate the influence of bi-material moulds, the addition of metallic coatings, and to integrate a system of cooling channels.

+ The development of a printable, high-temperature, thermally conductive and mechanically resistant material formulation was carried out by ComposiTIC for the laboratory and pilot batches, then by NANOVIA for the final industrial formulation, i.e. 55 formulations.

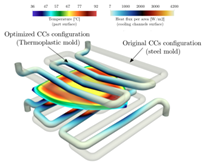

+ A methodology for optimising the cooling channels was validated by the Thermal and Energy Laboratory in Nantes. CERO was able to test the injection on a SAMFAST prototype mould.

Project Manager

Antoine Barbé

antoine.barbe@univ-ubs.fr