+ Limiting the environmental impact of fishing rods while improving and optimising performance.

+ Producing the first 100% recyclable rods and spars.

+ Proposing a recycling procedure involving product recall, recycling and re-use.

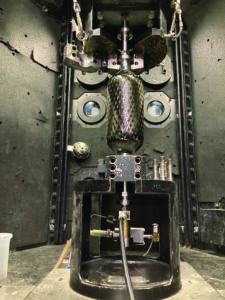

+ Mastering the filament winding process for thermoplastic matrix composites.

Project Manager

Yves Grohens

Find out more

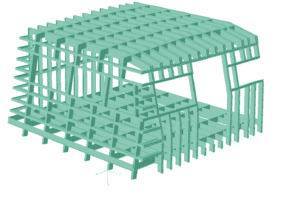

The Gwalenn Du project aims to develop an innovative automated process for manufacturing fishing rods and spars for the boating industry from 100% recyclable materials.

These products are currently manufactured from thermosetting materials that are not very diverse and cannot be recycled. The project aims to limit the environmental impact to meet user expectations, while improving and optimising performance.

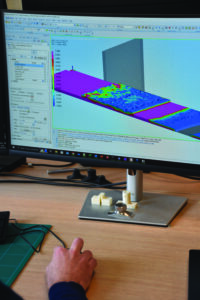

The research will lead to the development of a technique for the automated design and implementation of thermoplastic composites by filament winding.

The development of such a process should also enable production to be relocated, while improving product quality.

Project goals

- Industrial & technical

Developing innovative automated processes to:

– Reduce production costs.

– Increase product performance.

– Improve product quality. - Environment

– Produce the first 100% recyclable boating rods and spars.

– Offer a recycling network (product recall, recycling, re-use). - Scientific

– Master the filament winding process for thermoplastic matrix composites.

By loading this video, you agree to the privacy policy of Youtube.

Supports