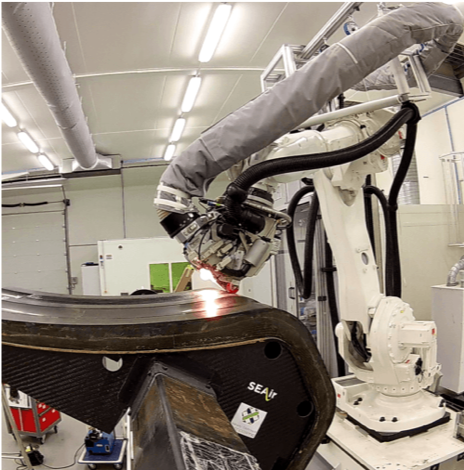

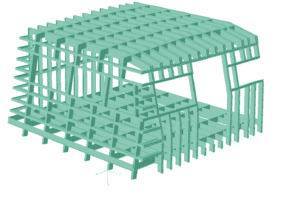

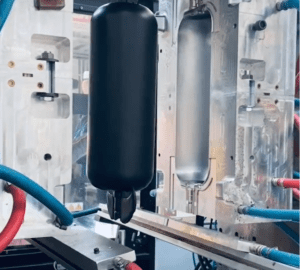

+ Use of automated fibre placement processes and 3D printing to produce foils of optimum quality.

+ Validation of technical suitability through geometric and mechanical characterisation.

+ Economic assessment, from design to manufacture, for both single foils and series of foils.

Project Manager

Yves Grohens

Find out more

The foil: a revolution underway in the world of boating

A booming market for the marine sector… and one that could rapidly expand to the motorboating and even naval sectors.

Significant potential for improvement in terms of:

– design (optimisation)

– manufacturing (reliability, cost reduction)

An open area of scientific and technological investigation

Objectives of FOILAddiCT

– Study the technical feasibility and economic relevance of automated manufacturing processes and their coupling, to produce prototype or mass production foils.

– Developing and mastering innovative, industrial and optimised processes.

– Acquiring a technological lead enabling industrial partners to position themselves at the forefront of major markets in the nautical sector.

By loading this video, you agree to the privacy policy of Youtube.

Supports